Chapper: Carvable Hull-and-Pack for Subtractive Manufacturing

ACM SIGGRAPH Asia 2025 (Journal track, TOG)

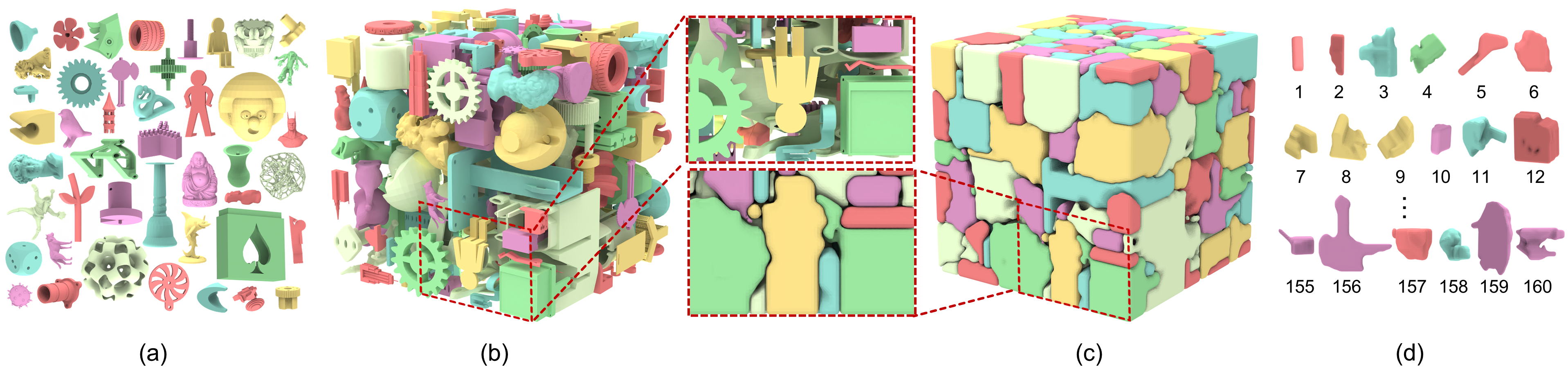

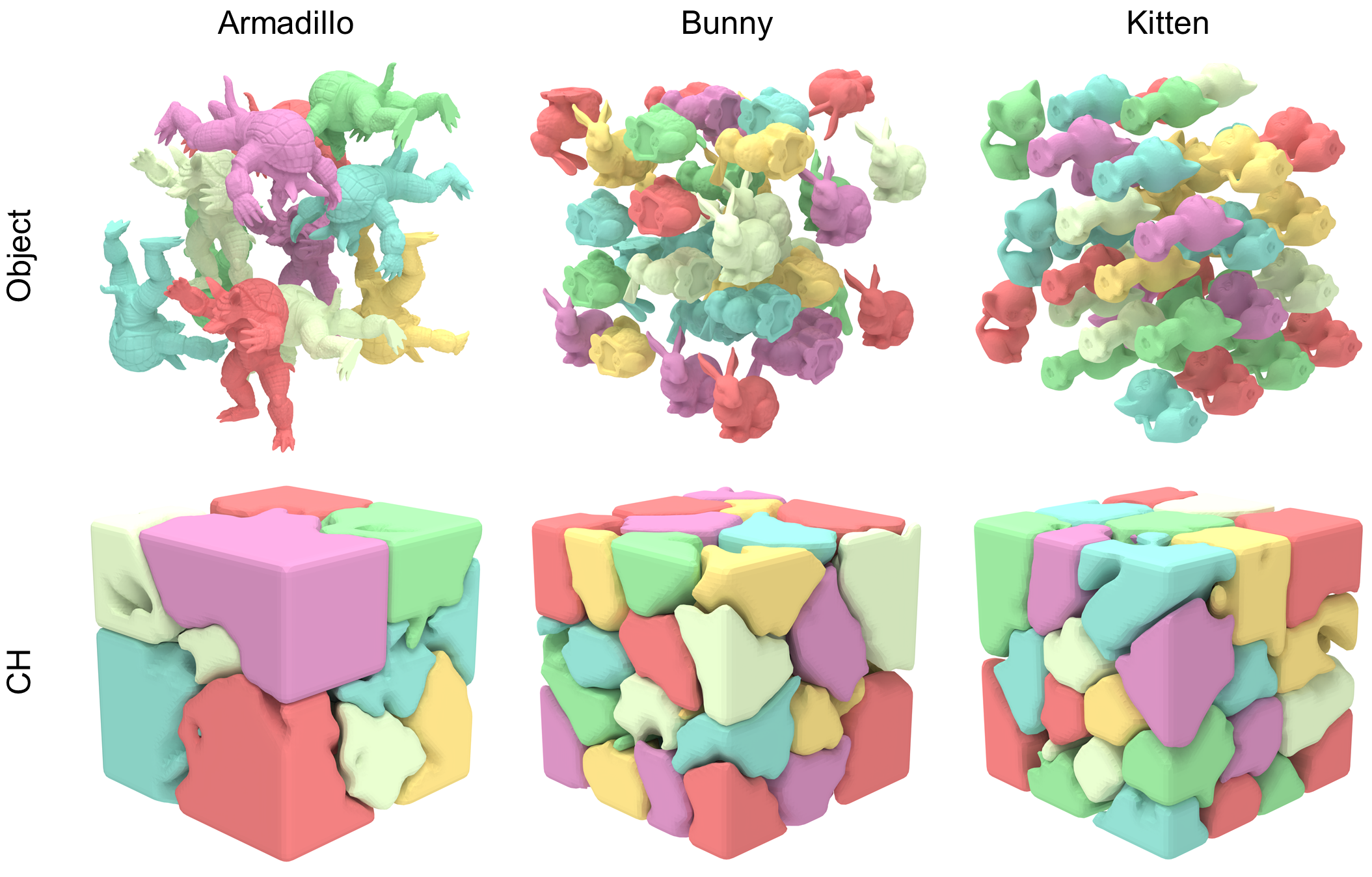

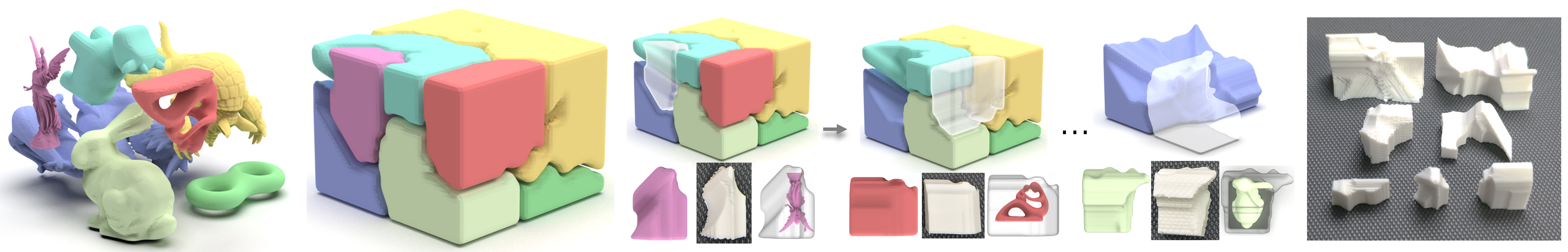

Fig. 1. Our Chapper framework achieves compact packing with high space utilization while ensuring all objects satisfy the carvable constraints. We introduce a novel carving hull extraction method that computes a carving hull for each object, capturing both its shape and subtractive manufacturability, constrained by neighboring geometry and encoding machining paths. This figure illustrates our method packing 160 complex benchmark objects (a) densely into a cube (b) with 21.6 % space utilization. It also produces a disassembly sequence (d) and corresponding carving hulls (c). Each object is fully enclosed by its carving hull, which guides toolpath generation and enables feasible disassembly.

Abstract

Tightly cutting raw materials into a set of carvable objects, known as

the

stock cutting problem, is a necessary step in subtractive manufacturing.

This problem can be framed as a 3D irregular object packing task, aiming

to fit as many objects as possible within a predefined container. While

previous packing algorithms can generate dense, non-overlapping, and even

interlocking-free configurations, they cannot satisfy carvable constraints.

This paper introduces the carvable hull-and-pack problem, which inte-

grates irregular object packing with subtractive manufacturing. This problem

is more challenging than general 3D packing, as it requires ensuring the

carvability of each object and generate the disassembly sequence. To address

this, we first define a novel geometric hull, called carving hull, which ac-

counts for both the object's shape and the cutter accessibility, constrained by

the real-time distribution of surrounding objects. Then we present Chapper,

an effective solution to co-optimize the planning of carving hull pack and

disassembly sequence to maximize space utilization while preserving the

carvable constraints. Given a raw material and a list of generic 3D objects,

our algorithm starts with densely packing each object into the material

with a pre-computed placement order, while simultaneously maintaining

a valid disassembly sequence. We solve the complex object-to-object and

cutter-to-object collisions by leveraging a discrete voxel representation. The

carvability of each object is also guaranteed in the packing process, where

we define a novel carvable metric to determine whether each object is carv-

able or not. Based on the packing result and the disassembly sequence, we

propose a clipped Voronoi-based volume decomposition method to generate

the actual carving hull for each object and finally create feasible cutting

tool paths on the carving hulls. Our approach effectively packs CAD and

freeform datasets, exhibiting a unique space utilization rate performance

compared to the alternative baseline.

Video

Pipeline

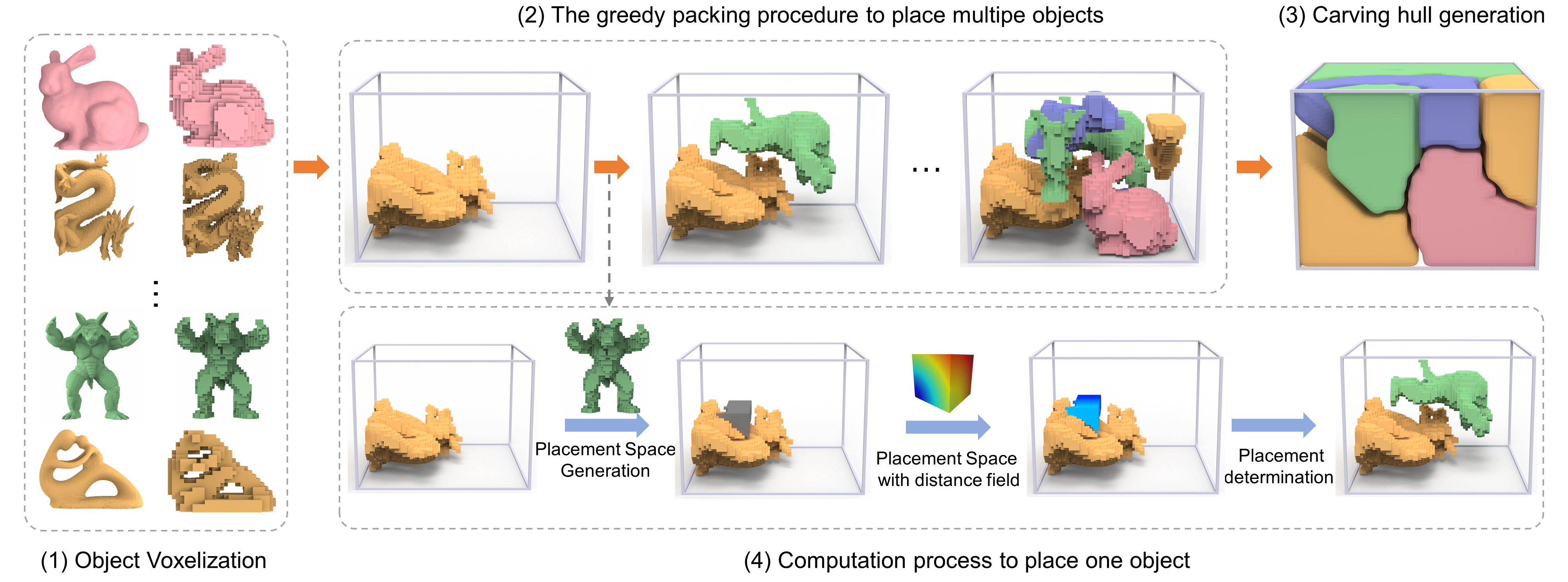

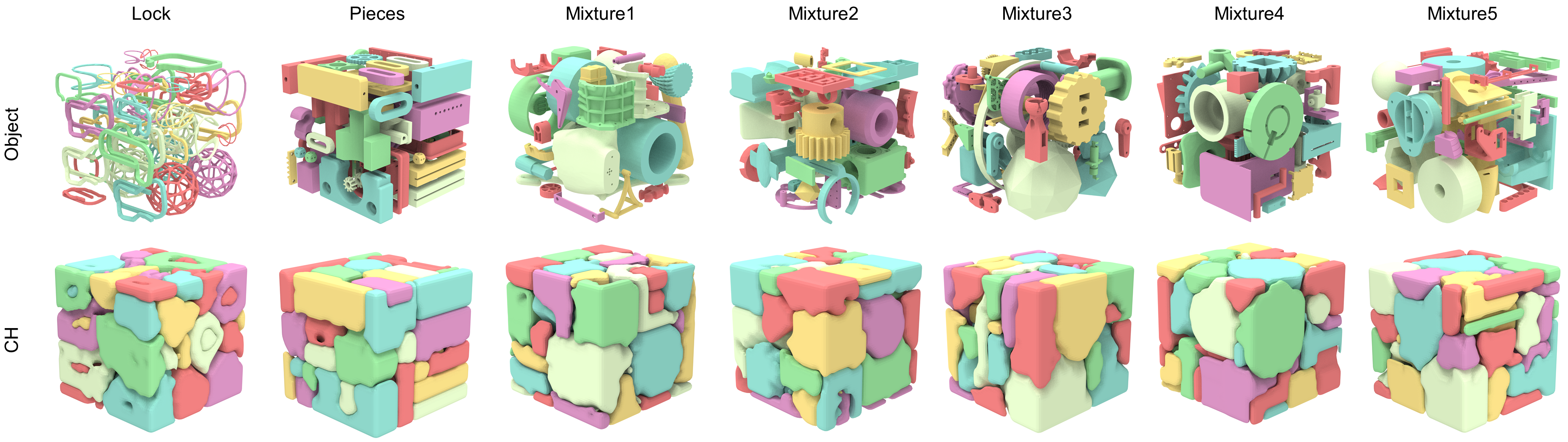

Fig. 2. Overview of the proposed Chapper algorithm. We begin by voxelizing the input objects (left row) and then apply a greedy algorithm to pack them in descending order of volume (top row). The bottom row illustrates the computation process for placing a single object into the container, as detailed in Sections 4.1,4.2, 4.3. First, we generate a feasible placement space that satisfies the collision-free constraint and partially fulfills the cutter-collision-free constraint. Next, we organize voxel positions within this space using a distance field and determine the optimal placement location for the object while verifying the carvable constraints. Additionally, throughout the packing process, we ensure a feasible disassembly sequence for each object.

Results

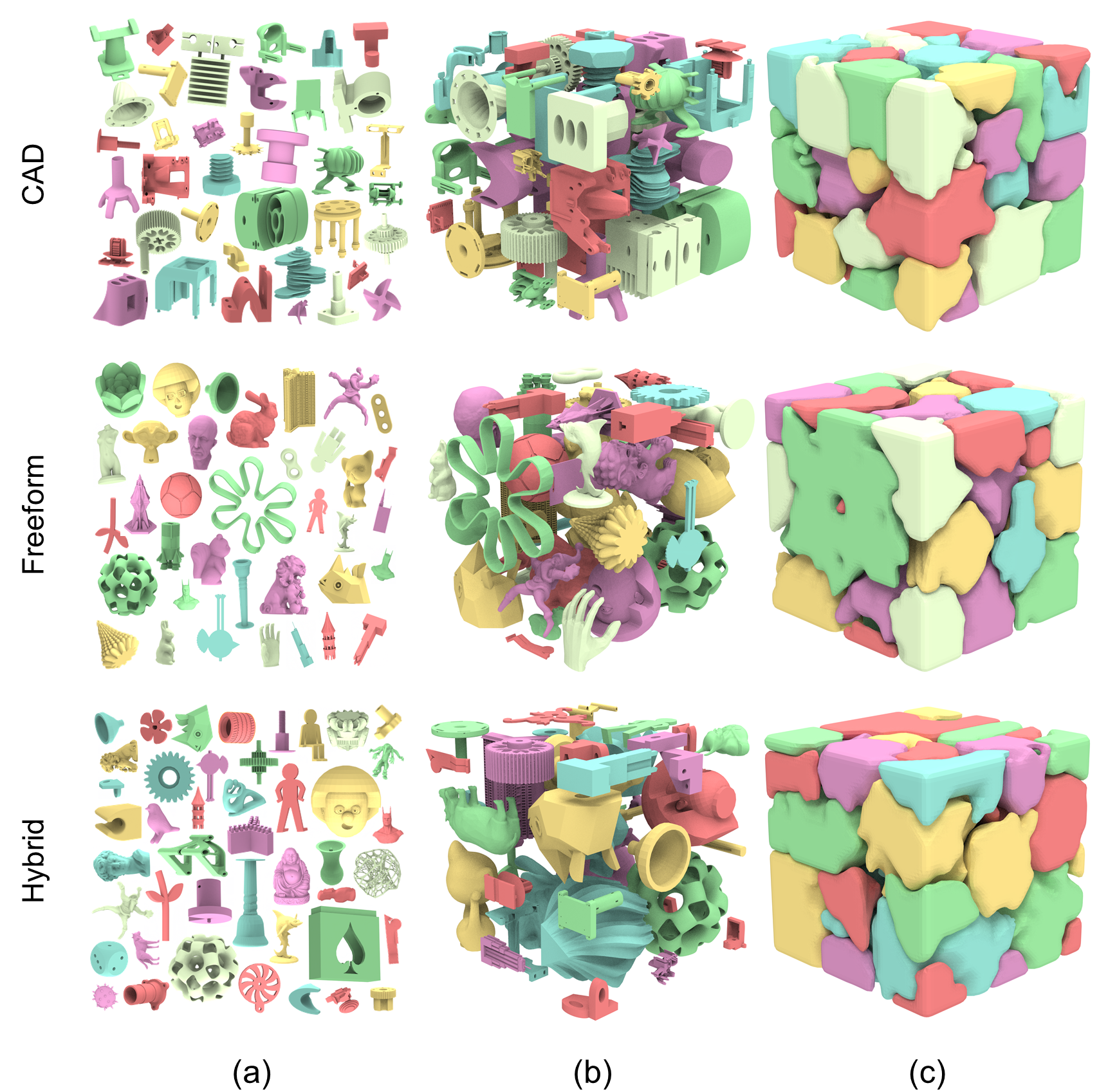

Fig. 3. Our 3D packing results on three proposed datasets, including irreg- ular CAD, freeform shapes, and hybrid. It ensures a high space utilization rate while allowing the cutter to access the gaps between the models for cutting.

Fig. 4. Testing our method in single-object scenarios to isolate the effects of packing-order variability.

Fig. 5. Packing results of our approach on the LOCKS, PIECES, and MIXTURE datasets demonstrate its effectiveness across diverse scenarios.

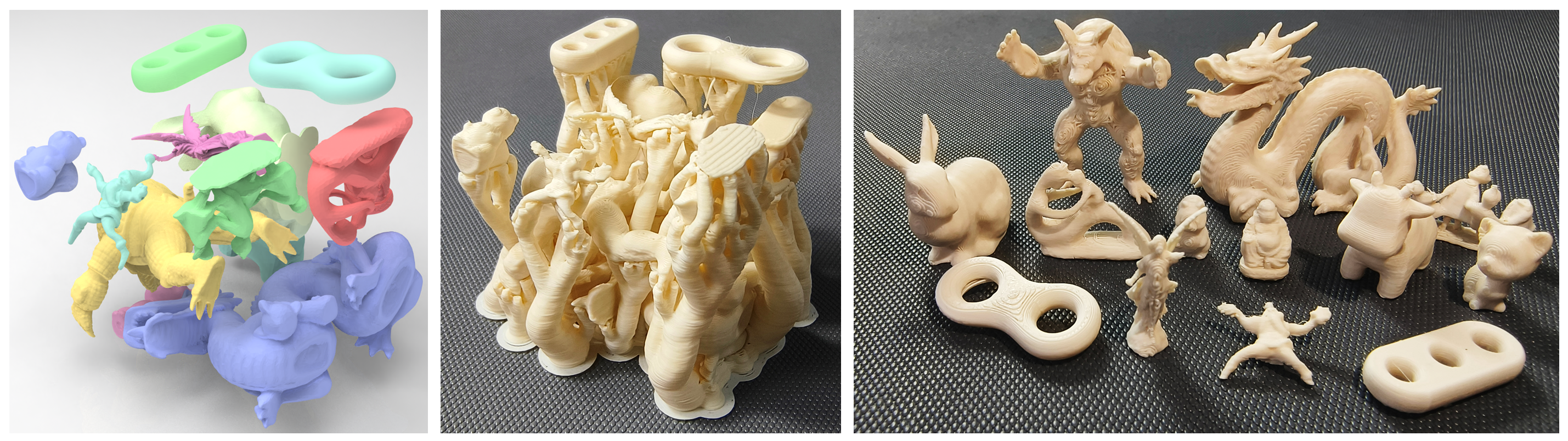

Fig. 6. Physical experiment for five-axis CNC machining. From left to right: our packing outcomes, the corresponding carving hulls, and the machining objects post-disassembly.

Fig. 7. Physical experiment for 3D printing support removal. From left to right: our packing outcomes, the printed item with supports, and objects post-disassembly with a handheld rotary tools.

Downloads